THE WORLD LEADER

in special hazard

fire suppression solutions

first to adapt to new technologies.

protection, Firetrace International supplies powerful,

flexible fire management solutions worldwide.

Firetrace Aerospace, a wholly-owned subsidiary of

Firetrace USA, applies the Firetrace core product line

to the aviation and defense markets.

Since its inception in 2000, Firetrace International

has been headquartered in Scottsdale, Arizona, USA.

Growing from a modest 2,000 ft2 (185 m2) facility,

80,000 ft2 (7500 m2) of office and warehouse space in

its current facility.

To ensure timely, effective support around the world,

Firetrace also maintains sales offices in Sydney,

Singapore, New Delhi, Dubai and Johannesburg.

FIRETRACE HISTORY

1980s

Firetrace systems developed as a solution for the

frequent fires that occurred in farm harvesting

equipment due to mechanical failures and the build-up

of plant materials.

Firetrace’s robust tubing-based system proved

the ideal solution to the dirt, vibration and temperature

variations that made traditional automatic solutions

impractical.

2000

Firetrace International founded to market

Firetrace’s unique systems worldwide.

2011

Firetrace expanded its offering with a range of clean

agent engineered systems, and the development of

E4 – the next generation of engineered systems

designed specifically for the unique properties of

3MTM NovecTM 1230.

2015

Firetrace International acquired by Halma plc,

the market leader in specialist safety, health and

environmental technologies.

2018

Firetrace launches its new Dual Action System for

complex micro-environments, providing twice the

protection of a single local application or total

flooding system.

250,000+

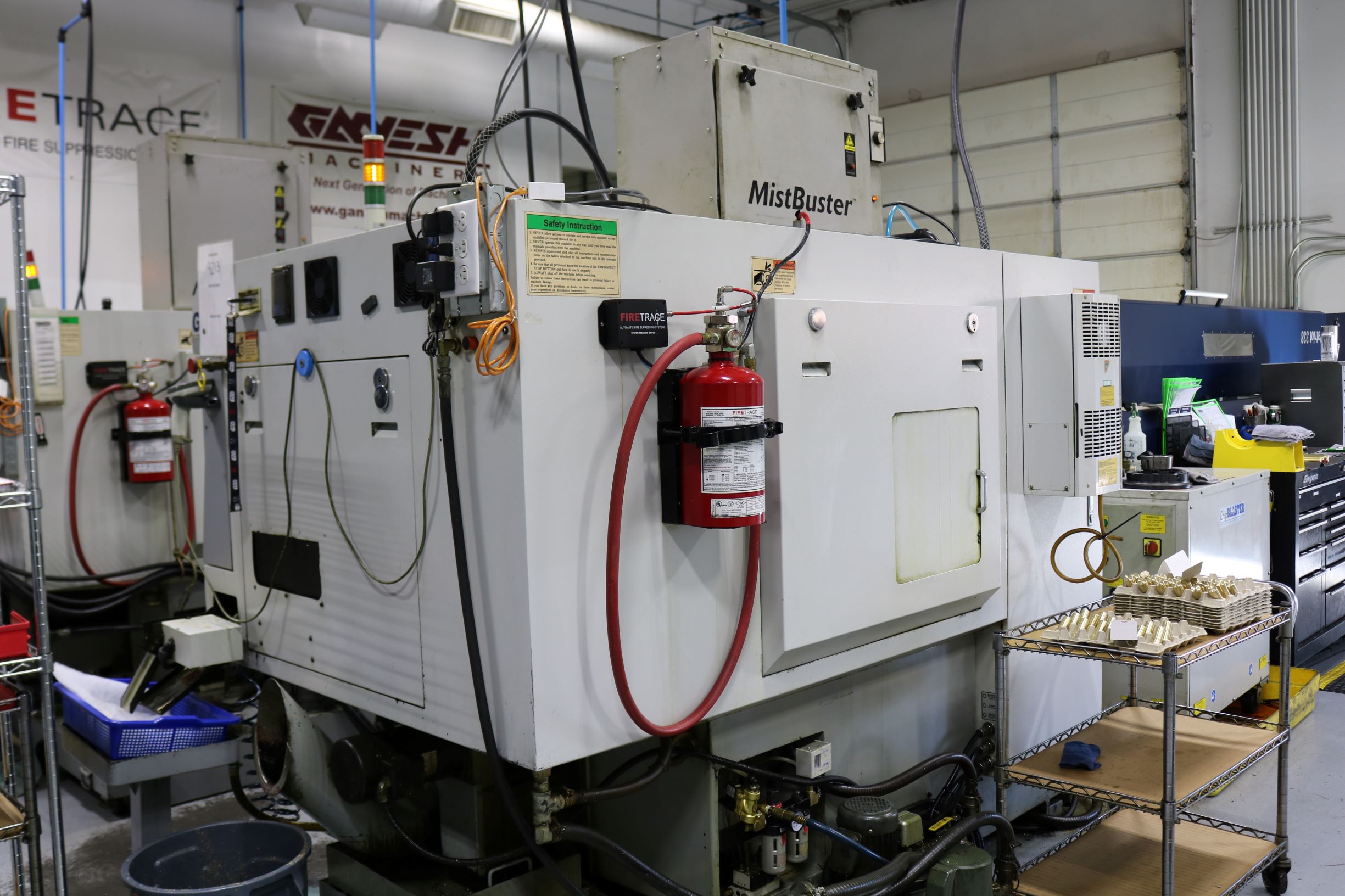

Firetrace systems have been installed around the world to date; in CNC machines, buses, electrical control panels, fume hoods, engine and generator compartments, hazardous storage cabinets and countless other applications.

PRE-ENGINEERED SYSTEMS:

The original is still innovating

Micro-environments are applications where the hazard is typically contained within a critical enclosure, such as equipment, machines, vehicles, or storage compartments

Firetrace systems can be installed in virtually any enclosed space where high-value assets are located, or where an increased risk of fire could be mitigated by an automatic fire suppression system.

THE FIRETRACE ADVANTAGE

The effectiveness of a genuine Firetrace system comes

from our proprietary polymer tubing that will rupture

when exposed to the heat and flame of a growing fire.

This specialized Firetrace Detection Tubing is UL

component listed, combines leak resistance, flexibility,

durability, and precise temperature sensitivity, in

order to react quickly when the heat from a fire is

present. The Firetrace tubing connects to one of our

custom engineered valves and a Firetrace cylinder

that contains the best fire suppression agent for a

particular hazard.

Firetrace systems operate without the need for any

power source – external or battery - and require no

releasing panel to operate.

Direct Release

A local application system that uses the Firetrace detection tubing to both sense the fire and deliver the agent to the protected space. When exposed to fire the tubing bursts, forming a nozzle that directs the suppression agent.

Indirect release system

A total flooding system that uses the Firetrace detection tubing only as a sensing device. Upon detection, agent is delivered into the protected space using pipes or hoses and fixed nozzles.

Dual action system

Combines the functionality of the direct local application system and indirect total flooding system. By delivering agent through both nozzles and the tubing burst, a more complete and effective suppression is achieved.

Choosing the right agent

Firetrace’s systems are compatible with most commercially available fire suppression agents, including:

FM-200™

FM-200™ Novec™ 1230

Novec™ 1230 Dry Chemical (ABC, BC, D)

Dry Chemical (ABC, BC, D) Foam

Foam Black Widow

Black Widow CO2

CO2FIRETRACE BENEFITS:

EXTREME ENVIRONMENTS

MAINTENANCE AND RECHARGE

24/7 UNINTERRUPTED SERVICE

GREATER FLEXIBILITY

ANY HAZARD LOCATION

OR DISCHARGES

AND DELIVERY

An evolution in engineered

clean agent systems

Efficiency

The unique features of FM-200® allow for fewer

nozzles, thus a less complex piping design, as

compared to other clean agents.

The unique features of FM-200® allow for fewer

nozzles, thus a less complex piping design, as

compared to other clean agents.

The larger area of coverage per nozzle using

FM-200® reduces the amount of agent needed

to extinguish a fire

The larger area of coverage per nozzle using

FM-200® reduces the amount of agent needed

to extinguish a fire

Cost

The price per pound of the FM-200® agent is lower

than other clean agents.

The price per pound of the FM-200® agent is lower

than other clean agents.

With less hardware required, FM-200® systems are

more economical.

With less hardware required, FM-200® systems are

more economical.

Risk

Safety for humans if the system is discharged.

Safety for humans if the system is discharged.

Safe for electronic equipment, minimizing

downtime if a fire occurs.

Safe for electronic equipment, minimizing

downtime if a fire occurs.

SYSTEM SIZES

MORE PERFORMANCE

MORE DESIGN FLEXIBILITY

MORE SAVINGS

Choosing the right agent

Firetrace’s systems are compatible with most commercially available fire suppression agents, including:

ARCHIVES

ARCHIVES ENERGY STORAGE SYSTEMS

ENERGY STORAGE SYSTEMS MUSEUMS

MUSEUMS ART GALLERIES

ART GALLERIES FLAMMABLE LIQUID STORAGE

FLAMMABLE LIQUID STORAGE OFFSHORE DRILLING

OFFSHORE DRILLING BANK VAULTS

BANK VAULTS HISTORICAL BUILDINGS

HISTORICAL BUILDINGS PORTABLE ENCLOSURES

PORTABLE ENCLOSURES CONTROL ROOMS

CONTROL ROOMS HOSPITALS

HOSPITALS TELECOMMUNICATIONS

TELECOMMUNICATIONS DATA CENTERS

DATA CENTERS LIBRARIES

LIBRARIES TEST LABS

TEST LABS